1000 mm Injection Mould Plastic Pallets

Price 1100 INR/ Piece

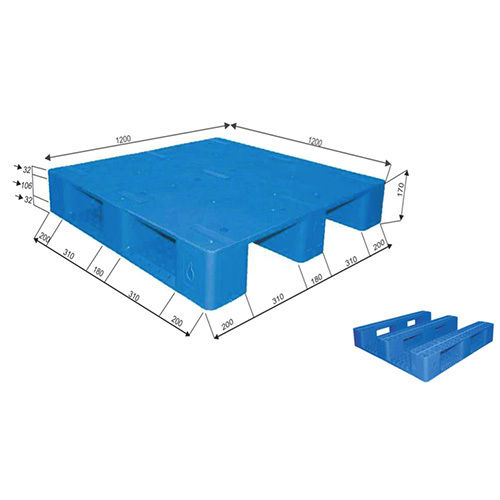

1000 mm Injection Mould Plastic Pallets Specification

- Metal Type

- Non-Metallic

- Weight

- 8-15 kg (varies by model)

- Deck Type

- Single / Double Face

- Dimension (L*W*H)

- 1000 mm x 1000 mm x 150 mm (approx)

- Forklift

- Yes

- Dynamic Load

- Up to 1000 kg

- Load Capacity

- Up to 1000 kg (Dynamic), Up to 4000 kg (Static)

- Handlift

- 2-way

- Static load

- Up to 4000 kg

- Entry Type

- 2-way / 4-way

- Product Type

- Industrial Pallet

- Material

- Plastic

- Plastic Type

- HDPE / PP

- Style

- Mesh

- Pallet Type

- Injection Mould Plastic Pallet

- Size

- Different Available

- Color

- Blue / Black / Custom

- Surface Type

- Anti-slip / Slip-resistant

- Temperature Resistance

- -30°C to +60°C

- UV Protection

- Available

- Edge Type

- Rounded Corners

- Moisture Absorption

- Nil

- Compliance

- RoHS / REACH / ISPM-15 Exempt

- Application

- Warehousing, Logistics, Export, Food & Pharma Industries

- Recyclability

- 100% Recyclable

- Cleaning

- Easy to Clean

- Stackability

- Nestable / Stackable

- Chemical Resistance

- High

1000 mm Injection Mould Plastic Pallets Trade Information

- Minimum Order Quantity

- 500 Pieces

- Supply Ability

- 5000 Pieces Per Month

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About 1000 mm Injection Mould Plastic Pallets

Pallets made of plastic that have undergone the injection moulding process are one sort of pallet. As part of the manufacturing process known as injection moulding, molten plastic is injected into a mould cavity, cooled, and hardened to create the desired shape.

The following are some salient qualities and traits of injection-molded plastic pallets:

2. Design: Block pallets and stringer pallets are only two examples of the many configurations that injection-molded plastic pallets may be made in. Forklifts or pallet jacks can approach block pallets from all four sides thanks to their four-way entry method. With notches for forklift entrance, stringer pallets have two long parallel supports.

3. Dimensions and Load Limit: Pallets made of injection-molded plastic are available in a variety of sizes to meet varied load requirements. Based on the design and structural strengthening, the load capacity of these pallets can range from a few hundred kilogrammes to several tonnes.

4. Consistent, precise, and uniform production of pallets is made possible by injection moulding. This guarantees that every pallet has the same measurements and load-carrying capacity, enabling dependable stacking and cargo transportation.

5. Pallets made of injection-molded plastic are intended to be strong and long-lasting. They are suited for use in a variety of situations, including food processing, pharmaceuticals, and other industries with strict hygiene standards. They are resistant to moisture, rot, insects, and chemicals.

6. Plastic pallets remove the possibility of splinters, nails, or protruding hardware associated with hardwood pallets, improving safety and hygiene. Additionally, they are simple to maintain and clean, encouraging improved hygiene and lowering the possibility of contamination in delicate sectors.

7. Recyclability: Pallets constructed of injection-molded plastic can be recycled after their useful lives because they are frequently made of recyclable components. This supports sustainability initiatives and lessens the environmental damage caused by conventional methods of pallet disposal.

Pallets made of injection-molded plastic provide a number of benefits over those made of other materials. They are adaptable to fit certain industry requirements, lightweight, strong, and hygienic. To ensure effective and secure flow of goods, they can be utilised in a variety of supply chain applications, such as warehousing, logistics, transportation, and storage.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Injection Mould Plastic Pallets Category

HDPE Injection Moulded Plastic Pallets

Price 2000.00 INR / Piece

Minimum Order Quantity : 50 Pieces

Product Type : HDPE Injection Moulded Plastic Pallets

Color : Blue

Plastic Type : HDPE

Size : Standard

Black Injection Mould Plastic Pallets

Price 900 INR / Piece

Minimum Order Quantity : 500 Pieces

Product Type : Plastic Pallet

Color : Black

Plastic Type : HDPE (High Density Polyethylene)

Size : Different Available

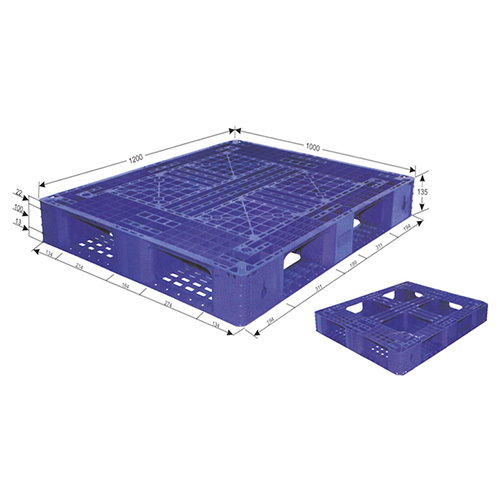

Industrial Injection Moulded Plastic Pallets

Price 2450 INR / Piece

Minimum Order Quantity : 50 Pieces

Product Type : Industrial Injection Moulded Plastic Pallets

Color : Blue

Plastic Type : HDPE

Size : 1200 x 1000 x 135 mm

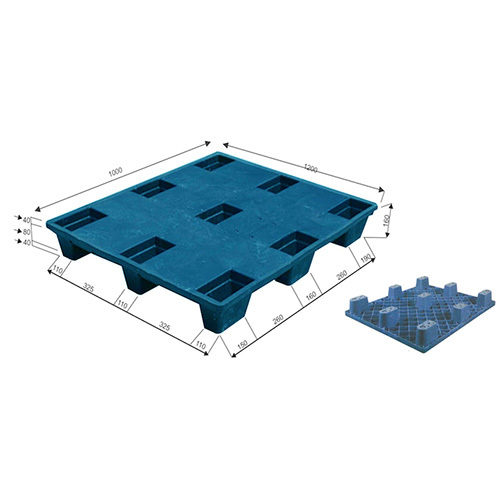

Grey Injection Moulded Plastic Pallets

Price 2450 INR / Piece

Minimum Order Quantity : 50 Pieces

Product Type : Grey Injection Moulded Plastic Pallets

Color : Black

Plastic Type : HDPE

Size : 1200 x 1000 x 135 mm

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free